One has to note that ensuring protection from environmental factors is very crucial when selecting the electric enclosures, especially for outdoor or industrial equipment. Indeed, NEMA 3 and NEMA 4 enclosures have been good picks, but to get the right one for your needs, you should know the difference. This guide takes you through what each standard entails and thereby assist you in selecting the correct enclosure for your application.

What is NEMA 3 (IP54)?

These enclosures serve outdoor applications to safeguard enclosed equipment from rain falls along with snow and sleet during average weather periods. Ideal for moderate industrial or telecommunication applications.

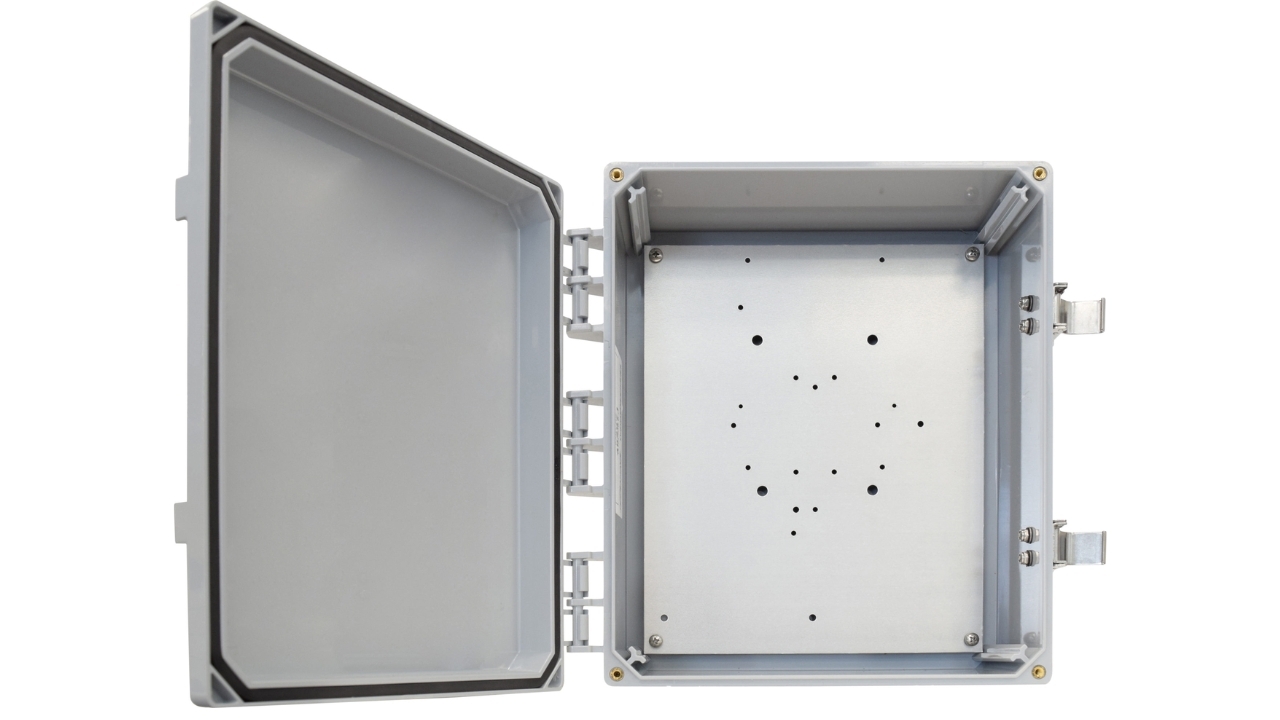

What is NEMA 4? (IP66)

IP66 enclosures will offer better protection than NEMA 3. The enclosure will protect equipment from falling rain, sleet, snow, splashing water, and hose-directed water. Rugged and reliable, these enclosures are ideally suited for harsh applications typically encountered on industrial sites.

Key Differences Between NEMA IP54 and NEMA IP66

● Protection against Weather Elements:

The rain and snow along with sleet gives devices protection under IP54 classification but NEMA IP66 provides complete waterproof protection through hose spraying and exposure to snow and sleet. NEMA IP66 enclosures offer maximum defense against rain, snow, sleet weather conditions as well as direct spraying of water.

● Material and Construction:

NEMA 3 enclosures are typically made from stainless steel or aluminum to provide adequate safeguarding against various environmental factors. On the other hand, NEMA 4 enclosures use materials like stainless steel because this would serve to be a mean for harsher environments. They are non-corrosive and are designed for impact or abrasion resistance.

● Environmental Suitability:

NEMA 3 enclosures should suffice if the outdoor conditions of your equipment installation are modest and if there is only sporadic dust and moisture. In that sense, a tough industrial environment would make it necessary to consider using NEMA 4 enclosures, which are made to provide the necessary protection in case machinery is to be exposed to chemicals or frequent wash-downs.

● Cost Considerations:

In mild environments, NEMA 3 enclosures are low-cost and provide good protection. On the other hand, rising costs characterize NEMA 4 enclosures, whose additional costs are because of robust features that do assure best protection. Although somewhat costly, NEMA 4 is a very good investment in harsh environments, particularly the added cover needed.

Applications of NEMA 3 Enclosures

● Outdoor Environments:

The best area of application for a NEMA 3 enclosure is the installation of electrical equipment to be used outdoors. Common applications are in utility power meters, traffic control systems, and telecommunications equipment. They offer protection from falling dirt, rain, and sleet, which are not supposed to flow inside the enclosure at any harmful quantity.

● Industrial and Telecommunication Equipment:

When you are working in an industrial or telecommunications setup with equipment which is exposed to dusty moist atmospheres but with no direct contact of water, then best suited will be the NEMA 3 enclosure. This panel is designed to guard against moderate environmental exposure.

Applications of NEMA 4 Enclosures

● Harsh Industrial Settings:

Extremes of industrial exposure benefit from IP66 enclosure applications. IP66 enclosures present strong safeguarding capabilities during operations that involve regular cleaning procedures and water stream management or chemical usage. These are popular in manufacturing, food processing, or chemical plants.

● Regular Cleaning and Protection:

The NEMA 4 enclosures are apt where the equipment is cleaned at regular intervals with water sprays. It might be the right product if the equipment needs to survive daily through multiple wash-downs, for example, in a food and beverage treatment plant or an atmosphere with strict hygiene standards.

Choosing Between NEMA 3 and NEMA 4 Enclosures

● Evaluating Your Environmental Needs:

When opting between IP54 and IP66 enclosures the essential step involves determining the required environmental conditions. The IP54 enclosure rating provides the necessary protection for light weather conditions when raining or affected by slight dust. IP66 enclosures offer superior protection against harsh conditions of frequent wash-downs and heavy rain and hose-driven water.

● Protection Requirements:

Examine what your safeguards require. In such cases, NEMA 3 will cover against rain and dust; however, where direct water exposure is common, this may not be enough. Therefore, NEMA 4 is designed to face much harsher conditions, such as water sprays and physical impacts, and hence is suitable for more demanding industrial applications.

● Cost vs. Protection:

Think about the trade-off between the cost and protection. NEMA 3 would cost less, whereas NEMA 4 would be very important if the equipment requires a higher level of protection. It would then secure reliability and safety well into the future.

Get High Quality NEMA 3 and NEMA 4 Enclosures from Xinvic

Xinvic presents an array of NEMA 3 and NEMA 4 enclosures, in great design, which can assure very reliable protection for electrical equipment. You can check from the range most appropriate to your needs and secure that solution.

Conclusion

Once you understand the differences between the two types of enclosures—NEMA 3 and NEMA 4—you should be able to confidently choose the best way to protect your equipment. Be it basic protection against mild weather or additional security in hostile environs, Xinvic has a lasting solution for every enclosure need of yours in a dependable manner.

Frequently Asked Questions

Can IP54 enclosures be used in wet environments?

Industrial IP54 enclosures provide outdoor protection which allows your equipment to resist rain as well as snow and sleet. IP54 enclosures function as protection against moisture but not for constant submersion. Choose IP66 enclosures to protect equipment from water exposure because IP54 enclosures have limited resistance to water and moisture

Is NEMA 4 more suitable for harsh industrial settings?

Yes, NEMA 4 enclosures are basically designed for a harsh industrial environment. The protection does not limit itself to the weather elements but also to water spray, hose-directed water, and even chemical exposure.

What are the typical materials used in IP54 and IP66 enclosures?

A NEMA 3 enclosure is generally made up of steel or aluminum and particularly provides protection against moderate environmental conditions. On the other hand, NEMA 4 enclosures use tougher material, such as stainless steel, which can stress greater chemical and water impacts.

What industries typically use NEMA 4 enclosures?

These enclosures are frequently used in the manufacturing, food processing, pharmaceutical, chemical processing, and wastewater treatment plants. Such industries require equipment that is guarded against water, dust, and continuous wash-downs; hence, NEMA 4 enclosures are idyllic.